Page 50 - 2021-ENGLISH-CATALOG

P. 50

Product Catalogue www.durulsan.com

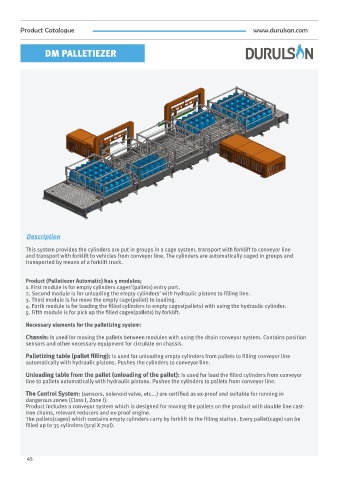

DM PALLETIEZER

Description

This system provides the cylinders are put in groups in a cage system, transport with forklift to conveyor line

and transport with forklift to vehicles from conveyor line. The cylinders are automatically caged in groups and

transported by means of a forklift truck.

Product (Palletiezer Automatic) has 5 modules;

1. First module is for empty cylinders cages'(pallets) entry port.

2. Second module is for unloading the empty cylinders’ with hydraulic pistons to filling line.

3. Third module is for move the empty cage(pallet) to loading.

4. Forth module is for loading the filled cylinders to empty cages(pallets) with using the hydraulic cylinder.

5. Fifth module is for pick up the filled cages(pallets) by forklift.

Necessary elements for the palletizing system:

Chassis: Is used for moving the pallets between modules with using the chain conveyor system. Contains position

sensors and other necessary equipment for circulate on chassis.

Palletizing table (pallet filling): Is used for unloading empty cylinders from pallets to filling conveyor line

automatically with hydraulic pistons. Pushes the cylinders to conveyor line.

Unloading table from the pallet (unloading of the pallet): Is used for load the filled cylinders from conveyor

line to pallets automatically with hydraulic pistons. Pushes the cylinders to pallets from conveyor line.

The Control System: (sensors, solenoid valve, etc...) are certified as ex-proof and suitable for running in

dangerous zones (Class I, Zone I).

Product includes a conveyor system which is designed for moving the pallets on the product with double line cast-

iron chains, relevant reducers and ex-proof engine.

The pallets(cages) which contains empty cylinders carry by forklift to the filling station. Every pallet(cage) can be

filled up to 35 cylinders (5cyl X 7cyl).

45